Introduction

ARK 390 arc spray coating is iron-based with a high-boron structure. It also has high bond strength plus high hardness and wear resistance because its hard phase is formed from FeB.

Main features

- High chromium content

- High temperature oxidation resistant

- Good erosion wear resistance

- Good thermal shock resistance

- The oxide content in the coating is low

Typical applications

- Boiler tubes for pulverized coal-fired boilers and waste incinerators against high temperature oxidation, hot corrosion and erosion wear

- Steel converter, hoods and flue ducts.

Chemical composition of deposited metal (%)

| C | Ni | B | Si | Other | Fe |

|---|---|---|---|---|---|

| <1.0 | <1.0 | <5.0 | <1.0 | <1.0 | Balance |

Mechanical properties

| Bond Strength (MPa) Acc. to ASTM C633-01 | Micro-hardness (HV 0.1, kg/mm²) |

|---|---|

| 50–52 (Low carbon steel substrate) | 560–730 |

Coating properties

| Density (g/cm³) | % Prosity | % Deposition efficiency |

|---|---|---|

| 7.48 | <5 | 70–85 |

Recommended spraying parameters

| Diameter: in (mm) | Air pressure (MPa) | Current (A) | Voltage (V) |

|---|---|---|---|

| 1⁄16 (1.6) | 0.5–0.6 | 180–220 | 28–32 |

Diameters and packaging

| Diameter: in (mm) | Packaging: lb (kg) |

|---|---|

| 1⁄16 (1.6) | 27.5 (12.5) (Vacuum pack spool) |

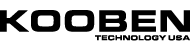

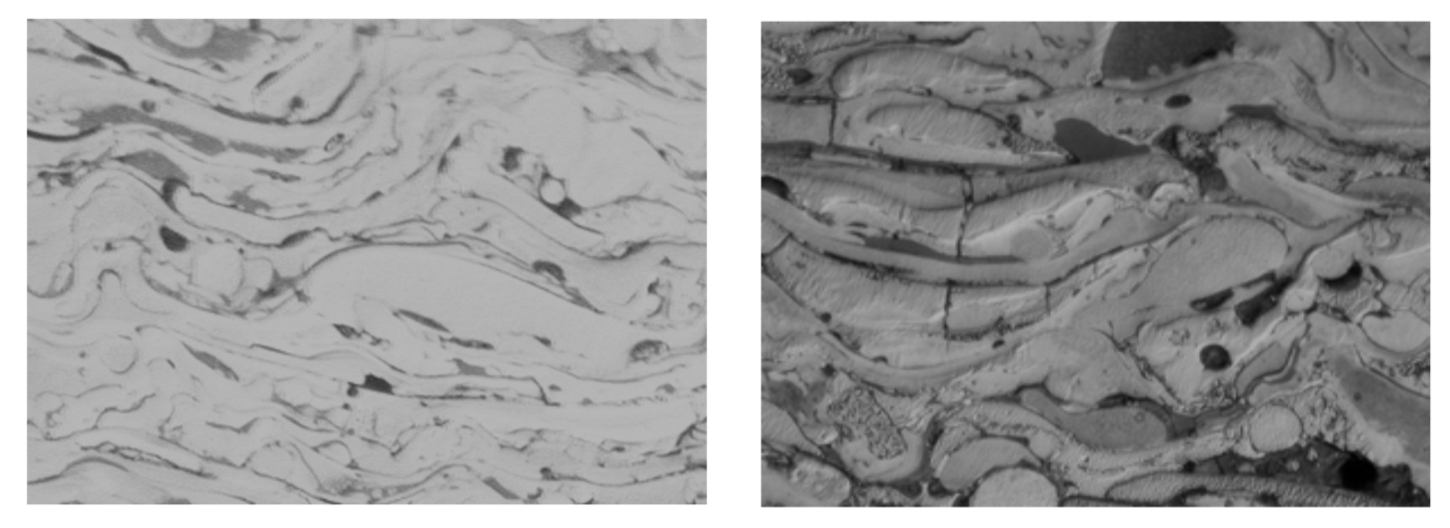

Metallographic photos

| Click here to download the datasheet for Kooben ARK 390. |